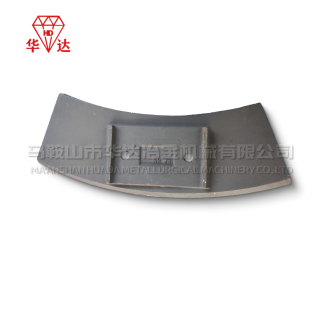

Lame de retour latérale résistante à l'usure du mélangeur

La lame de retour latérale résistante à l'usure du mélangeur est conçue pour une résilience élevée, réduisant l'usure opérationnelle et garantissant des performances constantes dans les processus de mélange à retour latéral.

Mixer Wear-Resistant Side Return Blade: Boost Mixing Efficiency and Durability

Introduction to Mixer Wear-Resistant Side Return Blades

Mixer side return blades are crucial components for the efficient operation of concrete mixers. Designed to guide and return the materials smoothly within the drum, they help maintain optimal material flow. Wear-resistant side return blades are built to endure harsh operating conditions, ensuring extended durability and minimal wear, thus improving overall mixing efficiency.

High-Quality Mixer Side Return Blades

Our mixer side return blades are crafted from high-quality, wear-resistant materials to withstand constant friction and abrasion. These blades are essential for handling the challenging mixing environment inside concrete mixers, providing a cost-effective solution for long-term use. The advanced construction of these wear-resistant side return blades helps reduce downtime and maintenance costs.

Benefits of Wear-Resistant Side Return Blades

Improved Material Flow: The design of the mixer side return blades ensures smooth and continuous material movement inside the mixer drum. This reduces material segregation and promotes uniform mixing, leading to high-quality concrete production.

Enhanced Durability: Made from robust, wear-resistant materials, the wear-resistant side return blades extend the life of your concrete mixer by reducing the need for frequent replacements and maintenance.

Optimal Performance: The efficiency of the side return blade manufacturing process ensures that these blades contribute to smooth mixing operations. Their design helps in maintaining an even distribution of materials, improving overall concrete quality.

Corrosion and Abrasion Resistance: The materials used in mixer side return blades offer resistance against corrosion and abrasion, making them ideal for use in challenging conditions where exposure to moisture and harsh chemicals is common.

Side Return Blade Manufacturing for Custom Solutions

Our side return blade manufacturing service allows for customization based on your concrete mixer’s specific needs. Whether it's for different mixer models or tailored to your production environment, we ensure the blades are designed to meet your exact requirements. Custom mixer side return blades provide the perfect fit for your equipment, optimizing its performance.

Applications of Mixer Wear-Resistant Side Return Blades

Concrete Batching Plants: Essential for producing high-quality concrete in large batches, ensuring the materials move consistently and evenly within the drum.

Ready-Mix Concrete Plants: The wear-resistant side return blades help prevent material segregation, maintaining the consistency and integrity of the mix.

Construction Sites: Ensure quick, reliable, and efficient concrete mixing, particularly where deadlines are critical.

Why Choose Our Mixer Wear-Resistant Side Return Blades?

Durability and Longevity: Our mixer side return blades are built to withstand the most demanding conditions, providing a long-lasting solution for your mixing needs.

Custom Manufacturing: We offer tailored side return blade manufacturingdes services pour répondre aux exigences spécifiques de votre équipement de mélange, garantissant une compatibilité parfaite et des performances optimales.

Performance mondiale prouvée:Reconnu dans le monde entier, notrelames de retour latérales résistantes à l'usuresont conçus pour gérer des conditions de mélange difficiles et améliorer l'efficacité globale de l'équipement.

Solutions rentables: Investir dans le durablelames de retour côté mélangeurcontribue à réduire les coûts opérationnels en minimisant la maintenance et les temps d’arrêt.

Conclusion

Choisir la haute qualitélames de retour latérales résistantes à l'usure du mélangeurgarantit le fonctionnement optimal de votre bétonnière. Ces lames améliorent le flux du matériau, optimisent la régularité du mélange et prolongent la durée de vie de l'équipement en réduisant l'usure. Grâce à notrefabrication de lames à retour latéralGrâce à nos services, vous bénéficiez de solutions sur mesure adaptées à vos équipements et à vos besoins opérationnels. Contactez-nous dès aujourd'hui pour en savoir plus sur nos produits et passer commande.